Rapida 76 HALF FORMAT

The Rapida 76 is a highly efficient press for a diversity of applications.

All Rapida 76 features and options are designed to assist you in reducing costs and maximizing your profitability, features such as:

- The simultaneous Plate Changing system (SPC) changes all plates in under 1 minute.

- Simultaneous washing processes using CleanTronic technology, drastically reduces job to a job transition time.

- Unique Sensoric Infeed System (DriveTronic SIS) offers maximum sheet accuracy, consistent feeder operation, and maximum printing uptime.

- Full preset capabilities throughout the press, ensuring precise and minimal job transition times.

- QualiTronic colour control and PDF check options quickly control the content, attain good colour and maintain tight colour tolerance on the run, minimize waste and maximize good sellable sheets on the floor.

- Highly flexible and customizable configurations of up to 10 units plus coater.

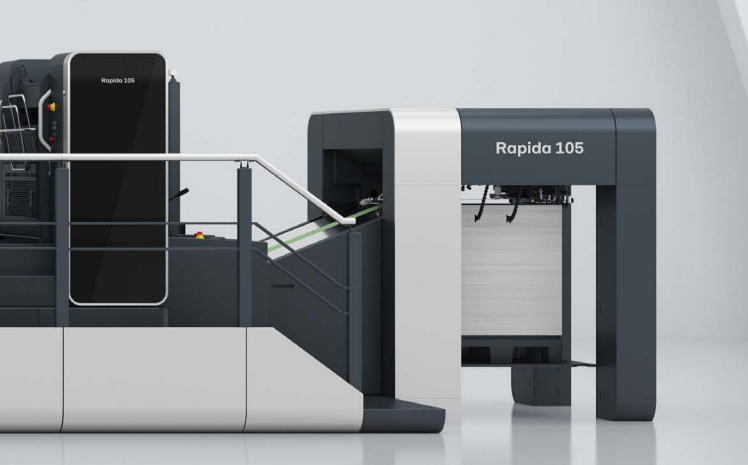

Rapida 105

More flexible than ever before

The Rapida 105 has for years stood as a synonym for reliability and an attractive price-performance ratio in medium-format sheetfed offset printing. The lasting market success has been founded above all on its superior substrate flexibility, outstanding ease of operation, robust construction, diverse possibilities for inline finishing, and last but not least, the excellent print quality.

Inline printing and finishing

The Rapida 105 is a genuine all-rounder. It handles an especially wide range of materials, from lightweight paper to board and micro flute corrugated substrates up to a thickness of 1.2 mm. Plastic films can also be printed.

Rapida 106

High end in medium format

The Rapida 106 has been the undisputed make-ready world champion in medium format since 2008. But not only that. With printing speeds of up to 20,000 sheets/h, it’s also the fastest in its format class. With uncompromising flexibility in terms of configurations, the Rapida 106 boasts the longest press installation in the world at 19 units. Wide-ranging combinations of printing and finishing units, plus numerous productivity options mean that every business in any segment can find their ideal press solution.

What makes Rapida 106 so unique:

- 20.000 s/h

- Side lay-free in-feed Drive Tronic SIS

- Simultaneous plate changing with Drive Tronic SPC

- Flying Job-change capability in seconds

- Anilox Loader and Drive Tronic SFC

Rapida 145 & 164

The New Dimension in Large Format

Koenig & Bauer has been the established market and technology leader in large-format sheetfed offset printing for many years. More than 50 years of experience in the building of large-format presses in unit design have flowed into the current Rapida 145 and Rapida 164 models. With up to 14 printing and inline finishing units, the most comprehensive large-format installations in the world carry the Koenig & Bauer badge. Packaging printing, in particular, has long since been the absolute domain of Koenig & Bauer Sheetfed.

Benefits of the Rapida 145 & Rapida 164

- Compact, space-saving design reduces investment outlay.

- Customer-specific configurations for cost-effective inline production.

- Perfectly automated, simultaneous makeready processes.

- Modern, intuitive operating system.

- Printing performance and makeready times similar to 3b format.